Centrifugal Air Compressor China and globle Market

The global centrifugal air compressor market has continued growing over the years and is expected to expand even more by 2028, reaching $8.6 billion. With increased urbanization and growing industries around the world, the demand for industrial centrifugal air compressors is going up.

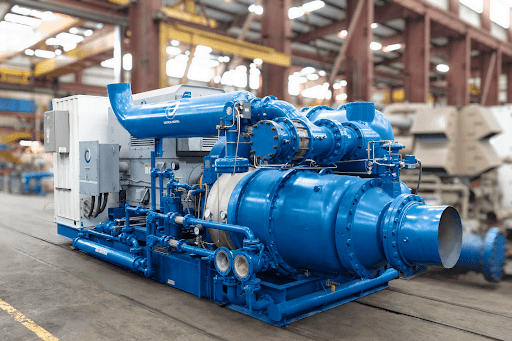

Centrifugal air compressors are widely used in many industries across the globe to offer high volumes of compressed air at relatively low prices. Additionally, these air compressors are robust, with extended lifelines making them cost-effective. If you ever wanted to know everything about centrifugal air compressors, this post got you covered.

What is a centrifugal air compressor?

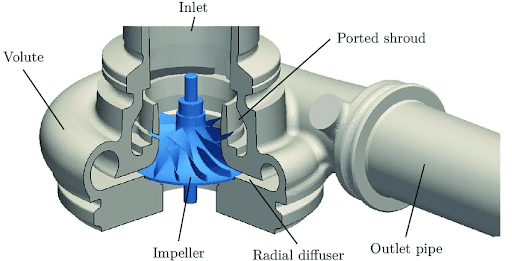

A centrifugal air compressor is a machine used to compress fluids using the radial acceleration of impellers surrounded by a compressor housing. The gas or oil compressed enters a centrifugal air compressor axially into the impellers and is discharged from the compressor radially. Centrifugal air compressors can be arranged in multiple stages to meet the demand for more compressed air. Every stage used adds to the overall pressure increase.

Many stages can be connected depending on the demand for compressed air in various centrifugal air compressor applications. For instance, oil and gas industries require multi-stage centrifugal compressors due to high-pressure demands. On the other hand, applications such as sewer treatment require moderate pressure, making single-stage centrifugal air compressors more suited for such tasks.

Centrifugal air compressor working principle

Air enters into the center of the rotating impellers radially due to the action of centrifugal force acting upon it. The radial movement of air creates high pressure and kinetic energy. The kinetic energy is converted into pressure as the air passes through the diffuser and a volute. This happens before the air moves to the center of the impeller.

Every stage plays a role in the overall increase in pressure. Depending on the air demand and application, multiple stages may be used by arranging every stage in series to create high pressure.

Currently, centrifugal air compressor manufacturers ad suppliers use ultra-high-speed electric motors to drive impellers. The design creates more compact centrifugal air compressors without oil lubrication or a gearbox. The same principle can be used to make small centrifugal air compressors without compromising performance.

What are the two types of centrifugal compressors?

Centrifugal air compressors can be categorized as:

- Single-stage compressor

- Multi-stage compressor

Single-stage centrifugal air compressors and multi-stage centrifugal air compressors work through the same principle. However, the construction of each unit differs significantly.

-

Single-stage centrifugal air compressor

A single-stage air compressor consists of a single runner that compresses air in the pressure ratio of up to 3:1. Single-stage air compressors are designed with a suspended impeller arrangement or a beam structure.

The impeller of a single-stage compressor is designed to be at the shaft’s non-driving. One of the advantages of a single-stage compressor is that it is more efficient and produces oil-free and surge-free air.

-

Multistage-stage compressor

Depending on the required airflow pattern, a multi-stage air compressor can have up to ten impellers arranged in series. Every stage of this unit has a constant temperature and compression ratio.

Multi-stage compressors can be set in dual-flow, straight-through, and compound arrangements. Additionally, they are beam-type, with runners designed between the radial bearings.

Why do we use a centrifugal compressor?

Air compressors are used to provide compressed air for various applications. Accordingly, air compressors are considered a workhorse of industries. In particular, centrifugal air compressors are used because they are more cost-effective compared to other compressor types. Additionally, they are often more robust and long-lasting. Applications that require high pressure and oil-free compressed air also rely on centrifugal air compressors.

Here are some industries that rely heavily on centrifugal air compressors:

- Oil and gas industries

- Automotive industry

- Superchargers

- Chemical plants

- Separation plants

- Pipeline compressors

These sectors depend on centrifugal air compressors for different reasons. For instance, these compressor units are used in pipelines to transfer natural gas from one point to another. Additionally, separation plants require centrifugal air compressors to manufacture purified gas products. All these are considered centrifugal air compressor applications.

Where is a centrifugal compressor used?

As outlined above, industries that require high volumes of compressed air use centrifugal air compressors to meet their air demands. Every machine has an individually designed impeller that allows it to function according to the requirements of every company. Every compressor is often customized and optimized to offer the required power range and pressure variant.

Since centrifugal air compressors are reliable units, they are used for different applications. In most cases, you will encounter these compressor units in various sectors, including food processing, pharmaceutical, oil and gas, chemical plants, wastewater treatment, renewable energy, textile, power, and automotive industries.

Centrifugal air compressor manufacturers

Centrifugal air compressor manufacturers and suppliers can be found in every corner of the world. However, the increasing number of centrifugal air compressor companies can make it hard to find the best manufacturer or supplier in the market. That is why you need in-depth knowledge about every manufacturer.

You need to identify certified centrifugal air compressor manufacturers and suppliers to get you started. Next, compare centrifugal air compressor prices to find what suits your budget. Alibaba and made-in-China.com can help you find reasonable price ranges. For instance, you will find compressor units with prices ranging from US$795 per unit to US$500000 per unit, depending on size and type.

Alternatively, you can opt for used centrifugal air compressors for sale or buy wholesale centrifugal air compressors at discounted prices.

What is the advantage of a centrifugal compressor?

Centrifugal air compressors are widely used in many industries for the following reasons:

- They offer a high-pressure ratio at low flow rates

- They are easy to design compared to other compressor units.

- They are more reliable than screw-type air compressors.

- They do not require a foundation.

- They are oil-free.

The bottom line

This article has outlined everything you need to know about centrifugal air compressors and their working principles. If you want to buy centrifugal air compressors, you need to know about these units and get as many answers as you can. Use this guide as your starting point, and ask questions before settling for any centrifugal compressor manufacturer.

By Zollent

By Zollent