The integrated and optimized pipeline design reduces the length and number of pipelines, thereby reducing the incidence of pipeline leakage and internal losses caused by the pipeline system.

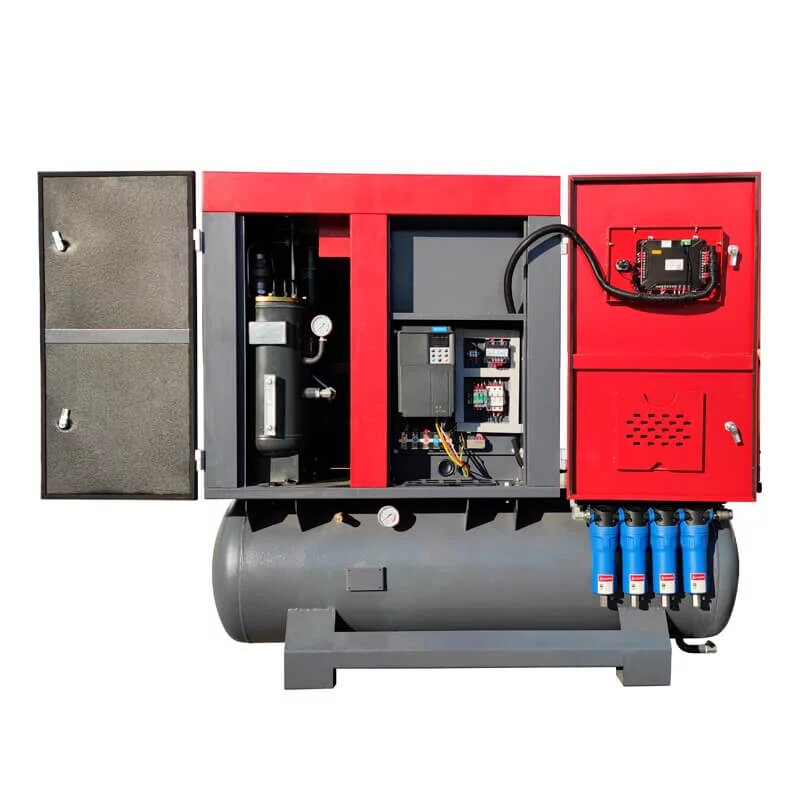

Easy-to-Use Compact Intergrated Air Compressor:

1.Integrated design with beautiful appearance, fewer parts, and connectors reduce the possibility of unit failure and leakage; direct discharge of dry compressed air, fully guarantee the quality of user terminal gas; greatly save customer installation costs and use space.

2.With new modular design structure, compact layout, ready to install and work.

3.After strict testing of the unit, the vibration value of the unit is far lower than the international standard.

4.The integrated and optimized pipeline design reduces the length and number of pipelines, thereby reducing the incidence of pipeline leakage and internal losses caused by the pipeline system.

5.Adopting a freeze dryer with excellent performance, a compact rotary refrigeration compressor, and a high cooling capacity configuration scheme to ensure reliable operation under high-temperature conditions.

| Sollant 4-in-1 Compact Integrated screw air compressor Parameter Table | |||||||||

| Model | SLT-7.5F | SLT-7.5V | SLT-11F | SLT-11V | SLT-15F | SLT-15V | SLT-15F | SLT-15V | |

| Motor | Power(kw) | 7.5 | 7.5 | 11 | 11 | 15 | 15 | 15 | 15 |

| Horsepower(ps) | 10 | 10 | 15 | 15 | 20 | 20 | 20 | 20 | |

| Air displacement/Working pressure (M³/Min./MPa) | 1.2/0.7 | 1.2/0.7 | 1.6/0.7 | 1.6/0.7 | 2.5/0.7 | 2.5/0.7 | 1.5/1.6 | 1.5/1.6 | |

| 1.1/0.8 | 1.1/0.8 | 1.5/0.8 | 1.5/0.8 | 2.3/0.8 | 2.3/0.8 | ||||

| 0.9/1.0 | 0.9/1.0 | 1.3/1.0 | 1.3/1.0 | 2.1/1.0 | 2.1/1.0 | ||||

| 0.8/1.2 | 0.8/1.2 | 1.1/1.2 | 1.1/1.2 | 1.9/1.2 | 1.9/1.2 | ||||

| Air outlet diameter | DN25 | DN25 | DN25 | DN25 | DN25 | DN25 | DN25 | DN25 | |

| Lubricating oil volume (L) | 10 | 10 | 16 | 16 | 16 | 16 | 18 | 18 | |

| Noise level dB(A) | 60±2 | 60±2 | 62±2 | 62±2 | 62±2 | 62±2 | 62±2 | 62±2 | |

| Driven method | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | |

| Start method | Υ-Δ | PM VSD | Υ-Δ | PM VSD | Υ-Δ | PM VSD | Υ-Δ | PM VSD | |

| External dimensions | Length (mm) | 1600 | 1600 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 |

| Width (mm) | 700 | 700 | 800 | 800 | 800 | 800 | 800 | 800 | |

| Height (mm) | 1500 | 1500 | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 | |

| Weight (kg) | 370 | 370 | 550 | 550 | 550 | 550 | 550 | 550 | |

| High-Efficiency Air-End 1.Large, oversized rotors for low rotational speed 2.New design - increased efficiency by 5-10% 3.Asymmetric rotor profile for increased sealing between rotors 4.Triple lip shaft seals 5.Oil and air leak-free design Air compressor manufacturers are developing eco-friendly and low-maintenance systems to encourage end-users to opt for next-generation products. Companies, such as Sollant. Growing investments by manufacturers in the R&D and redesigning activities for introducing a new range of energy-efficient air compressors is providing a positive outlook for the market size expansion. Rising energy costs and regulations limiting the energy consumption of industrial equipment have led to the development of energy-efficient compressors. Export markets cover more than 60 countries and regions worldwide • Branches throughout in China, the Philippines, Mexico and many other regions. • Working with over 500 long-term strategic partners. • Four independent R&D departments. • Two production bases covering 15,000². |

Q1: Are you factory or trade company?

A1:Yes,we are factory.Thank you.

Q2 : What's your factory's production capacity?

A2: About 1000 units per day.Thank you.

Q3: Warranty terms of your machine?

A3: One year for whole machine, two years for air end, technical support for life.Thank you.

Q4: Will you provide some spare parts of the machines?

A4: Yes, of course.Thank you.

Q5:Where is your factory located?

A5:Our factory is located in Shandong Linyi city which nears Qingdao port about 4 hours.Thank you.

Q6: Can you accept OEM orders?

A6: Yes, with professional design team, OEM orders are highly welcome.Thank you.

Q7: How much can you save if you buy our screw air compressor?

A7: Production of compressed air energy consumption may be more thaconsumption, can significantly reduce energy consumption, VS conon actual gas consumption, reduce the additional 44% to 25% of the energy saving program.

Due to the different freight rates in each country, you are welcome to contact us for specific freight charges.

Sollant is a professional company specializing in the sales, operation and maintenance of compressed air systems and energy-saving services. It is committed to providing users with stable, high-quality and low-cost compressed air. Provide product and service support for machinery, metallurgy, power generation, textile, chemical industry and other industries! After years of development, the company has a group of professional and technical personnel of air compression fluid equipment and rich experience in on-site engineering management, which can provide users with a full range of technical service support.