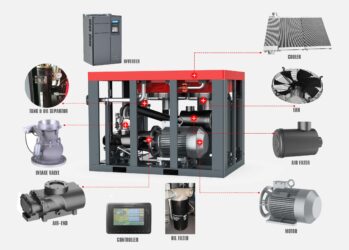

The unique design of the direct drive model provides users with multiple benefits. Crucially, a direct drive compressor has fewer moving parts, and therefore fewer parts that can cause wear. This quality makes them more suitable for heavy-duty industrial applications that belt-driven models cannot.

型号 ModelSLT-7.5FSLT-11FSLT-15FSLT-18.5FSLT-22FSLT-30FSLT-37FSLT-45FSLT-55FSLT-75FSLT-90FSLT-110FSLT-132FSLT-160FSLT-185FSLT-200FSLT-250FSLT-280FSLT-315FSLT-355F

| 电动机 Motor | 功率 Power(kw) | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 45 | 55 | 75 | 90 | 110 | 132 | 160 | 185 | 200 | 250 | 280 | 315 | 355 |

| 马力Horsepower(hp) | 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | 75 | 100 | 125 | 150 | 175 | 215 | 250 | 270 | 350 | 375 | 428 | 482 | |

| 排气量/排气压力 Air displacement/Working pressure (M³/Min./MPa) | 1.04/0.7 | 1.60/0.7 | 2.35/0.7 | 3.20/0.7 | 3.61/0.7 | 5.33/0.7 | 6.31/0.7 | 7.42/0.7 | 9.30/0.7 | 11.76/0.7 | 15.33/0.7 | 19.64/0.7 | 21.94/0.7 | 29.4/0.7 | 32.3/0.7 | 35.8/0.7 | 45.9/0.7 | 52.3/0.7 | 58.8/0.7 | 66.2/0.7 | |

| 1.03/0.8 | 1.59/0.8 | 2.34/0.8 | 2.89/0.8 | 3.59/0.8 | 4.85/0.8 | 6.28/0.8 | 7.38/0.8 | 9.25/0.8 | 11.70/0.8 | 15.25/0.8 | 19.54/0.8 | 21.83/0.8 | 28.3/0.8 | 31.9/0.8 | 34.4/0.8 | 44.0/0.8 | 48.5/0.8 | 54.0/0.8 | 61.0/0.8 | ||

| 0.99/1.0 | 1.59/1.0 | 1.94/1.0 | 2.70/1.0 | 3.58/1.0 | 4.50/1.0 | 6.22/1.0 | 7.27/1.0 | 9.02/1.0 | 11.97/1.0 | 15.16/1.0 | 19.42/1.0 | 21.58/1.0 | 25.0/1.0 | 28.5/1.0 | 32.6/1.0 | 36.3/1.0 | 44.6/1.0 | 48.5/1.0 | 53.9/1.0 | ||

| 0.77/1.2 | 1.34/1.2 | 1.92/1.2 | 2.24/1.2 | 2.86/1.2 | 3.10/1.2 | 3.54/1.2 | 6.17/1.2 | 7.10/1.2 | 8.72/1.2 | 11.8/1.2 | 15.011.2 | 19.09/1.2 | 21.15/1.2 | 23.32/1.2 | 29.53/1.2 | 33.8/1.2 | 38.2/1.2 | 44.5/1.2 | 48.2/1.2 | ||

| 出气口尺寸 Air outlet diameter | DN20 | DN25 | DN25 | DN25 | DN25 | DN40 | DN40 | DN40 | DN50 | DN50 | DN50 | DN65 | DN65 | DN65 | DN65 | DN80 | DN100 | DN100 | DN125 | DN100 | |

| 系统润滑油量 Lubricating oil volume (L) | 10 | 16 | 16 | 18 | 18 | 30 | 30 | 30 | 65 | 65 | 72 | 90 | 90 | 90 | 180 | 180 | 200 | 200 | 200 | 200 | |

| 噪音 Noise level dB(A) | 60±2 | 62±2 | 62±2 | 64±2 | 64±2 | 66±2 | 66±2 | 66±2 | 68±2 | 68±2 | 70±2 | 70±2 | 70±2 | 75±3 | 75±3 | 77±3 | 78±3 | 82±3 | 85±3 | 85±3 | |

| 驱动方式 Driven method | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | |

| 启动方式 Start method | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | |

| 外形尺寸 Extenal dimensions | 长度 Length (mm) | 950 | 1150 | 1150 | 1350 | 1350 | 1500 | 1500 | 1500 | 1900 | 1900 | 2450 | 2450 | 2450 | 3400 | 3760 | 2650 | 3000 | 3000 | 3300 | 3300 |

| 宽度 Width (mm) | 670 | 820 | 820 | 920 | 920 | 1020 | 1020 | 1020 | 1260 | 1260 | 1660 | 1660 | 1660 | 2100 | 2100 | 1488 | 1740 | 1740 | 2200 | 2200 | |

| 高度 Height (mm) | 1030 | 1130 | 1130 | 1230 | 1230 | 1310 | 1310 | 1310 | 1600 | 1600 | 1700 | 1700 | 1700 | 2260 | 2260 | 1900 | 2100 | 2100 | 2100 | 2100 | |

| 机组重量 Weight (kg) | 250 | 400 | 400 | 550 | 550 | 700 | 750 | 800 | 1750 | 1850 | 1950 | 2200 | 2500 | 3200 | 3200 | 4400 | 4700 | 4950 | 5600 | 6500 | |

As the name suggests, the motor is directly connected to the air pump in a direct drive air compressor. Air compressors do not need any intermediate pulleys, which also means that the speed of the motor is proportional to the speed of the compressor. With such a simple and efficient design, direct drive air compressors offer many advantages in everyday use.

Since these models have a direct connection between the compressor and the motor, they require fewer parts replacement. This also means that direct drive air compressors cost far less to maintain over time than any other type. A direct connection also means that any energy produced by the motor will be used to run the pump without any loss. It is rare to see such good use of the energy produced in any other type of air compressor.