Fixed Speed Air Compressor

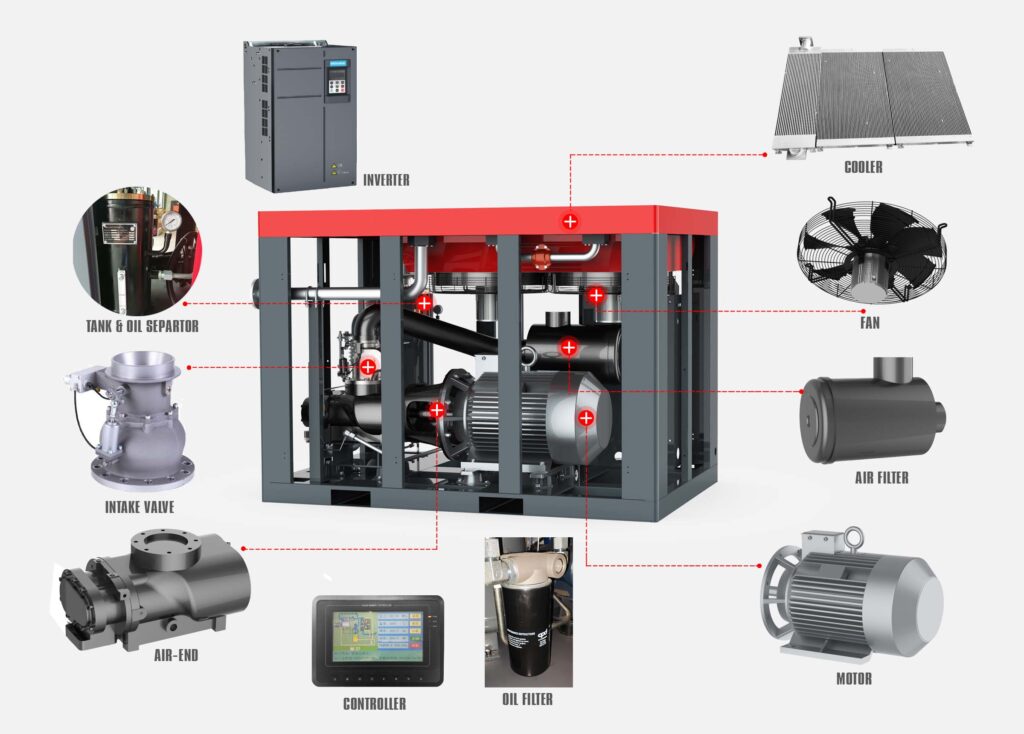

The optimally designed rotor profile of the power frequency air compressor achieves low energy consumption while maximizing the volumetric efficiency; the power frequency air compressor conforms to high-level machining and assembly accuracy, and the configuration of large-scale high-precision heavy-duty bearings further ensures the main engine reliability.

ModelSLT-7.5FSLT-11FSLT-15FSLT-18.5FSLT-22FSLT-30FSLT-37FSLT-45FSLT-55FSLT-75FSLT-90FSLT-110FSLT-132FSLT-160FSLT-185FSLT-200FSLT-250FSLT-280FSLT-315FSLT-355F

| Fixed Speed Screw Air Compressor Specification | |||||||||||||||||||||

| Motor | Power(kw) | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 45 | 55 | 75 | 90 | 110 | 132 | 160 | 185 | 200 | 250 | 280 | 315 | 355 |

| Horsepower(hp) | 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | 75 | 100 | 125 | 150 | 175 | 215 | 250 | 270 | 350 | 375 | 428 | 482 | |

| Air displacement/Working pressure (M³/Min./MPa) | 1.04/0.7 | 1.60/0.7 | 2.35/0.7 | 3.20/0.7 | 3.61/0.7 | 5.33/0.7 | 6.31/0.7 | 7.42/0.7 | 9.30/0.7 | 11.76/0.7 | 15.33/0.7 | 19.64/0.7 | 21.94/0.7 | 29.4/0.7 | 32.3/0.7 | 35.8/0.7 | 45.9/0.7 | 52.3/0.7 | 58.8/0.7 | 66.2/0.7 | |

| 1.03/0.8 | 1.59/0.8 | 2.34/0.8 | 2.89/0.8 | 3.59/0.8 | 4.85/0.8 | 6.28/0.8 | 7.38/0.8 | 9.25/0.8 | 11.70/0.8 | 15.25/0.8 | 19.54/0.8 | 21.83/0.8 | 28.3/0.8 | 31.9/0.8 | 34.4/0.8 | 44.0/0.8 | 48.5/0.8 | 54.0/0.8 | 61.0/0.8 | ||

| 0.99/1.0 | 1.59/1.0 | 1.94/1.0 | 2.70/1.0 | 3.58/1.0 | 4.50/1.0 | 6.22/1.0 | 7.27/1.0 | 9.02/1.0 | 11.97/1.0 | 15.16/1.0 | 19.42/1.0 | 21.58/1.0 | 25.0/1.0 | 28.5/1.0 | 32.6/1.0 | 36.3/1.0 | 44.6/1.0 | 48.5/1.0 | 53.9/1.0 | ||

| 0.77/1.2 | 1.34/1.2 | 1.92/1.2 | 2.24/1.2 | 2.86/1.2 | 3.10/1.2 | 3.54/1.2 | 6.17/1.2 | 7.10/1.2 | 8.72/1.2 | 11.8/1.2 | 15.011.2 | 19.09/1.2 | 21.15/1.2 | 23.32/1.2 | 29.53/1.2 | 33.8/1.2 | 38.2/1.2 | 44.5/1.2 | 48.2/1.2 | ||

| Air outlet diameter | DN20 | DN25 | DN25 | DN25 | DN25 | DN40 | DN40 | DN40 | DN50 | DN50 | DN50 | DN65 | DN65 | DN65 | DN65 | DN80 | DN100 | DN100 | DN125 | DN100 | |

| Lubricating oil volume (L) | 10 | 16 | 16 | 18 | 18 | 30 | 30 | 30 | 65 | 65 | 72 | 90 | 90 | 90 | 180 | 180 | 200 | 200 | 200 | 200 | |

| Noise level dB(A) | 60±2 | 62±2 | 62±2 | 64±2 | 64±2 | 66±2 | 66±2 | 66±2 | 68±2 | 68±2 | 70±2 | 70±2 | 70±2 | 75±3 | 75±3 | 77±3 | 78±3 | 82±3 | 85±3 | 85±3 | |

| Driven method | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | |

| Start method | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | |

| Extenal dimensions | Length (mm) | 950 | 1150 | 1150 | 1350 | 1350 | 1500 | 1500 | 1500 | 1900 | 1900 | 2450 | 2450 | 2450 | 3400 | 3760 | 2650 | 3000 | 3000 | 3300 | 3300 |

| Width (mm) | 670 | 820 | 820 | 920 | 920 | 1020 | 1020 | 1020 | 1260 | 1260 | 1660 | 1660 | 1660 | 2100 | 2100 | 1488 | 1740 | 1740 | 2200 | 2200 | |

| Height (mm) | 1030 | 1130 | 1130 | 1230 | 1230 | 1310 | 1310 | 1310 | 1600 | 1600 | 1700 | 1700 | 1700 | 2260 | 2260 | 1900 | 2100 | 2100 | 2100 | 2100 | |

| Weight (kg) | 250 | 400 | 400 | 550 | 550 | 700 | 750 | 800 | 1750 | 1850 | 1950 | 2200 | 2500 | 3200 | 3200 | 4400 | 4700 | 4950 | 5600 | 6500 | |

The screw air compressor adopts high-capacity compression components to achieve high efficiency and high reliability. The new design ensures extremely low system and compressed air temperatures. Guarantees optimum cooling and maximum service life for all components. Screw air compressors drive the compression components at the optimum speed for the application through an efficient drive system. Completely maintenance-free during normal operation.