Heatless adsorption dryer

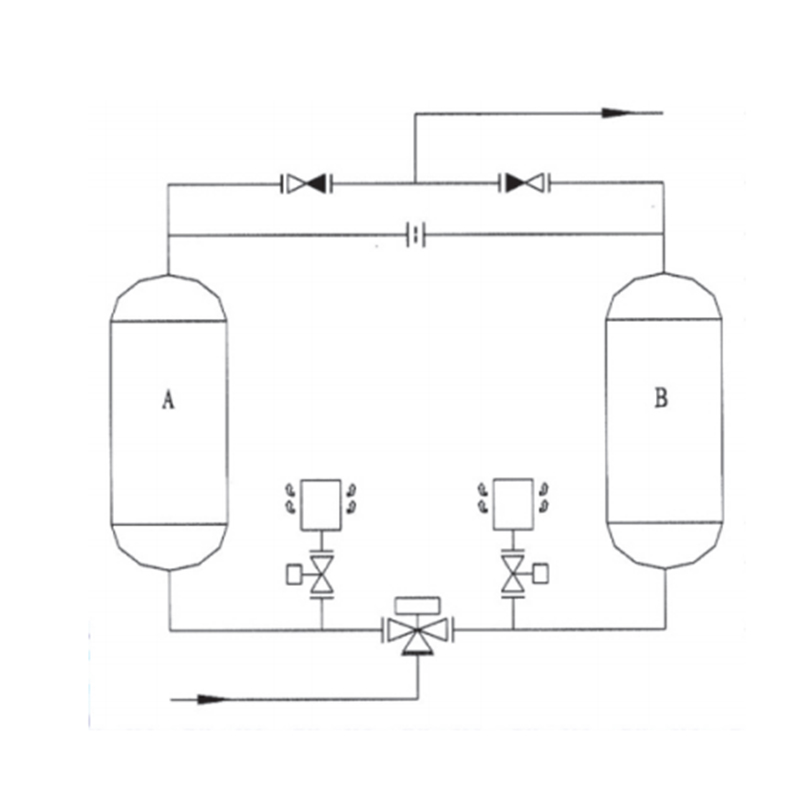

The working principle of heatless regenerative adsorption dryers is based on pressure swing adsorption (PSA). The adsorption and desorption working time of this device is short, the adsorption heat generated by the adsorption process basically exists in the adsorption bed, and the desorption process is approximately an isothermal process. The heatless regeneration adsorption dryer needs to consume a certain amount of product gas for adsorbent regeneration during the analysis process, but the total energy consumption is smaller than the heating regeneration adsorption dryer.

The heatless regenerative adsorption dryer is a device for drying compressed air according to the principle of pressure swing. It absorbs the moisture in the compressed air under pressure to dry the compressed air, and uses a part of the dry compressed air for purging during decompression. The adsorbent is used to regenerate the adsorbent. The two towers are alternated with each other to obtain dry compressed air. Different adsorbents are selected according to the dew point of the compressed air pressure. The commonly used adsorbents are activated alumina and molecular sieve.