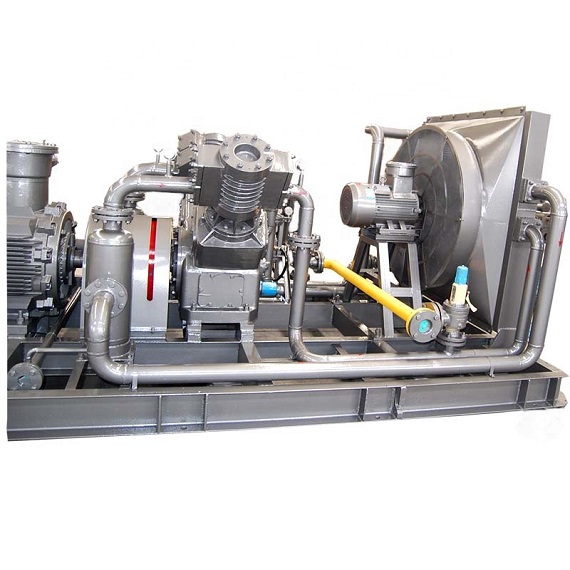

Landfill Gas Natural Gas Centrifugal Compressor applications gas lift (wellhead gas), down hole gas injection, landfill gas, natural gas gathering. The compressor for these processes is typically inlet pressure: 0.05-0.7Mpa, the outlet pressure: 6.8-17.2Mpa

| Type | Flow | Inlet pressure | Outlet pressure | Power | Speed | Weight | Dimension |

| Z | 305MCFD | 99psig | 493psig | 30kw | 777rpm | 1800kg | 94"×55"×55" |

| Z | 500MCFD | 35psig | 1000psig | 110kw | 888rpm | 4000kg | 126"×63"×55" |

| Z | 76MCFD | 29psig | 362psig | 30kw | 740rpm | 1500kg | 87"×47"×55" |

| Z | 152MCFD | 14.5psig | 174psig | 22kw | 730rpm | 1500kg | 87v×47"×55" |

| Z | 508MCFD | 290psig | 2320psig | 75kw | 740rpm | 3000kg | 118"X55"X55" |

| V | 85MCFD | 58psig | 1392psig | 15kw | 970rpm | 2500kg | 98"×55"×63" |

| V | 3531MCFD | 145psig | 203psig | 75kw | 740rpm | 5800kg | 142"×63"×63" |

| V | 2119MCFD | 87psig | 420psig | 200kw | 740rpm | 10000kg | 197"×102"×71" |

| D | 1300MCFD | 1psig | 116psig | 270kw | 1500rpm | 14000kg | 256"×110"×59" |

| M | 2542MCFD | 14.5psig | 43psig | 132kw | 740rpm | 8000kg | 142"×94"×59" |

| M | 30MMCFD | 1100psig | 4350psig | 2400kw | 980rpm | 85000kg |

|

Low maintenance cost natural gas centrifugal compressor

| Compressor stage | Name | Replace period |

| Stage I-2 | Piston ring | Replace time /4000 hour

|

| Guide ring | ||

| Inlet valve | Replace time /6000 hour | |

| Outlet valve | ||

| Outlet valve | ||

| Stage 3 | Piston ring | Replace time/2500 hour |

| Guide ring | ||

| Inlet valve plate | Replace time/each year | |

| Outlet valve plate |

Zollant has customized a matching air compressor for the cutting industry, which can meet the demanding requirements of various laser cutting equipment for water, oil, and particles in compressed air. The product adopts five-stage filtration and non-heat regeneration adsorption dryer. Pressure dew points up to -20 ° C ~ 70 ° C.

To explore in the cutting machine industry, the cost of liquid oxygen per barrel is generally about 70-90$. If your machine work 8 hours a day, you can consume this barrel of oxygen in about 4 days. The average cost of oxygen reduction is 19$ per day. If you are interested in reducing the cost of using the air compressor for laser cutting industry, feel free for contacting Zollant.