100% oil-free: Using the world’s most advanced oil-free water-lubricated screw compressor technology, compared with dry twin-screw, there is no lubricating oil in all parts of the air compressor, ensuring 100% oil-free compression and providing the most reliable oil-free compression Air Solutions. Convenient operation and maintenance: high degree of automation, operators do not need to undergo long professional training, and can realize unattended operation.

| Model | Working Pressure | Capacity | Power | Noise | Air outlet pipe diameter | Net weight | Dimensions(mm) | |||||

| bar | psig | m³/min | cfm | kw | hp | dB | Kg | Length | Width | Height | ||

| SLTOF-7FW | 7 | 102 | 1.2 | 42 | 7.5 | 10 | 58±3 | G1″ | 500 | 1135 | 800 | 1000 |

| 8 | 116 | 1.1 | 39 | 7.5 | 10 | 58±3 | G1″ | 500 | 1135 | 800 | 1000 | |

| 10 | 145 | 1 | 35 | 7.5 | 10 | 58±3 | G1″ | 500 | 1135 | 800 | 1000 | |

| SLTOF-11FW | 7 | 102 | 1.6 | 57 | 11 | 15 | 58±3 | G1″ | 500 | 1135 | 800 | 1000 |

| 8 | 116 | 1.5 | 53 | 11 | 15 | 58±3 | G1″ | 500 | 1135 | 800 | 1000 | |

| 10 | 145 | 1.3 | 46 | 11 | 15 | 58±3 | G1″ | 500 | 1135 | 800 | 1000 | |

| SLTOF-15FW | 7 | 102 | 2 | 71 | 15 | 20 | 60±3 | G1″ | 550 | 1400 | 1000 | 1200 |

| 8 | 116 | 1.8 | 64 | 15 | 20 | 60±3 | G1″ | 550 | 1400 | 1000 | 1200 | |

| 10 | 145 | / | / | 15 | 20 | 60±3 | G1″ | 550 | 1400 | 1000 | 1200 | |

| SLTOF-18.5FW | 7 | 102 | 3.1 | 109 | 18.5 | 25 | 61±3 | G1″ | 600 | 1400 | 1000 | 1200 |

| 8 | 116 | 2.8 | 99 | 18.5 | 25 | 61±3 | G1″ | 600 | 1400 | 1000 | 1200 | |

| 10 | 145 | 2.5 | 88 | 18.5 | 25 | 61±3 | G1″ | 600 | 1400 | 1000 | 1200 | |

| SLTOF-22FW | 7 | 102 | 3.7 | 131 | 22 | 30 | 61±3 | G1″ | 655 | 1400 | 1000 | 1200 |

| 8 | 116 | 3.4 | 120 | 22 | 30 | 61±3 | G1″ | 655 | 1400 | 1000 | 1200 | |

| 10 | 145 | 3 | 106 | 22 | 30 | 61±3 | G1″ | 655 | 1400 | 1000 | 1200 | |

| SLTOF-30FW | 7 | 102 | 5.2 | 184 | 30 | 40 | 64±3 | G11/2″ | 1150 | 1920 | 1170 | 1320 |

| 8 | 116 | 4.7 | 166 | 30 | 40 | 64±3 | G11/2″ | 1150 | 1920 | 1170 | 1320 | |

| 10 | 145 | 4.3 | 152 | 30 | 40 | 64±3 | G11/2″ | 1150 | 1920 | 1170 | 1320 | |

| SLTOF-37FW | 7 | 102 | 6.1 | 215 | 37 | 50 | 64±3 | G11/2″ | 1200 | 1920 | 1170 | 1320 |

| 8 | 116 | 5.6 | 198 | 37 | 50 | 64±3 | G11/2″ | 1200 | 1920 | 1170 | 1320 | |

| 10 | 145 | 5 | 177 | 37 | 50 | 64±3 | G11/2″ | 1200 | 1920 | 1170 | 1320 | |

| SLTOF-45FW | 7 | 102 | 7.5 | 265 | 45 | 60 | 66±3 | G11/2″ | 1320 | 1920 | 1170 | 1320 |

| 8 | 116 | 6.8 | 240 | 45 | 60 | 66±3 | G11/2″ | 1320 | 1920 | 1170 | 1320 | |

| 10 | 145 | 6 | 212 | 45 | 60 | 66±3 | G11/2″ | 1320 | 1920 | 1170 | 1320 | |

| SLTOF-55FW | 7 | 102 | 10 | 353 | 55 | 75 | 66±3 | DN50 | 1520 | 1930 | 1320 | 1535 |

| 8 | 116 | 9 | 318 | 55 | 75 | 66±3 | DN50 | 1520 | 1930 | 1320 | 1535 | |

| 10 | 145 | 7.8 | 275 | 55 | 75 | 66±3 | DN50 | 1520 | 1930 | 1320 | 1535 | |

| SLTOF-75FW | 7 | 102 | 13 | 459 | 75 | 100 | 70±3 | DN50 | 1620 | 1930 | 1320 | 1535 |

| 8 | 116 | 12 | 424 | 75 | 100 | 70±3 | DN50 | 1620 | 1930 | 1320 | 1535 | |

| 10 | 145 | 10 | 353 | 75 | 100 | 70±3 | DN50 | 1620 | 1930 | 1320 | 1535 | |

| SLTOF-90FW | 7 | 102 | 15.5 | 547 | 90 | 120 | 70±3 | DN50 | 1800 | 1930 | 1320 | 1535 |

| 8 | 116 | 14 | 494 | 90 | 120 | 70±3 | DN50 | 1800 | 1930 | 1320 | 1535 | |

| 10 | 145 | 12.5 | 441 | 90 | 120 | 70±3 | DN50 | 1800 | 1930 | 1320 | 1535 | |

| SLTOF-110FW | 7 | 102 | 20 | 706 | 110 | 150 | 72±3 | DN80 | 3100 | 2300 | 1600 | 1750 |

| 8 | 116 | 18 | 636 | 110 | 150 | 72±3 | DN80 | 3100 | 2300 | 1600 | 1750 | |

| 10 | 145 | 16 | 565 | 110 | 150 | 72±3 | DN80 | 3100 | 2300 | 1600 | 1750 | |

| SLTOF-132FW | 7 | 102 | 25 | 883 | 132 | 175 | 72±3 | DN80 | 3250 | 2300 | 1600 | 1750 |

| 8 | 116 | 23 | 812 | 132 | 175 | 72±3 | DN80 | 3250 | 2300 | 1600 | 1750 | |

| 10 | 145 | 20 | 706 | 132 | 175 | 72±3 | DN80 | 3250 | 2300 | 1600 | 1750 | |

| SLTOF-160FW | 7 | 102 | 27 | 953 | 160 | 215 | 72±3 | DN100 | 4500 | 2860 | 1500 | 2020 |

| 8 | 116 | 25.5 | 901 | 160 | 215 | 72±3 | DN100 | 4500 | 2860 | 1500 | 2020 | |

| 10 | 145 | 24 | 848 | 160 | 215 | 72±3 | DN100 | 4500 | 2860 | 1500 | 2020 | |

| SLTOF-185FW | 7 | 102 | 30 | 1059 | 185 | 250 | 74±3 | DN100 | 4500 | 2860 | 1500 | 1750 |

| 8 | 116 | 28 | 989 | 185 | 250 | 74±3 | DN100 | 4500 | 2860 | 1500 | 1750 | |

| 10 | 145 | 25 | 883 | 185 | 250 | 74±3 | DN100 | 4500 | 2860 | 1850 | 1750 | |

| SLTOF-200FW | 7 | 102 | 36 | 1271 | 200 | 270 | 74±3 | DN125 | 4800 | 3150 | 1850 | 1750 |

| 8 | 116 | 33 | 1165 | 200 | 270 | 74±3 | DN125 | 4800 | 3150 | 1850 | 1750 | |

| 10 | 145 | 27 | 953 | 200 | 270 | 74±3 | DN125 | 4800 | 3150 | 1500 | 1750 | |

| SLTOF-250FW | 7 | 102 | 43 | 1519 | 250 | 350 | 74±3 | DN125 | 5200 | 3150 | 1500 | 1750 |

| 8 | 116 | 41 | 1448 | 250 | 350 | 74±3 | DN125 | 5200 | 3150 | 1500 | 1750 | |

| 10 | 145 | 38 | 1342 | 250 | 350 | 74±3 | DN125 | 5200 | 3150 | 1500 | 1750 | |

pressure in real time through the Internet. The running status of the machine can be realized in real time.

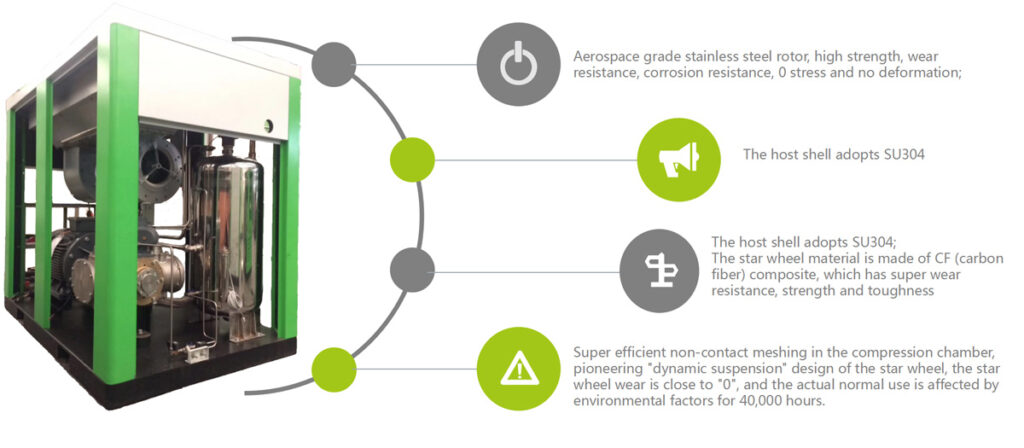

The oil-free screw air compressor compressor adopts the water-lubricated screw main engine produced by European technology, and is cast in copper alloy and formed at one time. Corrosion resistance, no deformation under high temperature and low temperature environment, independent lubricating water channel is used inside, which minimizes the wear of the main engine and reduces air pollution. Increase the flow rate of the air, adopt the original imported water separation and water softening system from Germany DDS.DS, increase the separation speed of water in the water vapor barrel, achieve a good water separation effect, and ensure that the water content of the exhaust is less than 2mg/m3.

The use of stainless steel screw and DDS.DS imported sealing material makes the sealing and meshing of the screw tighter, and the sealing material is more wear-resistant