Micro-heat adsorption dryer

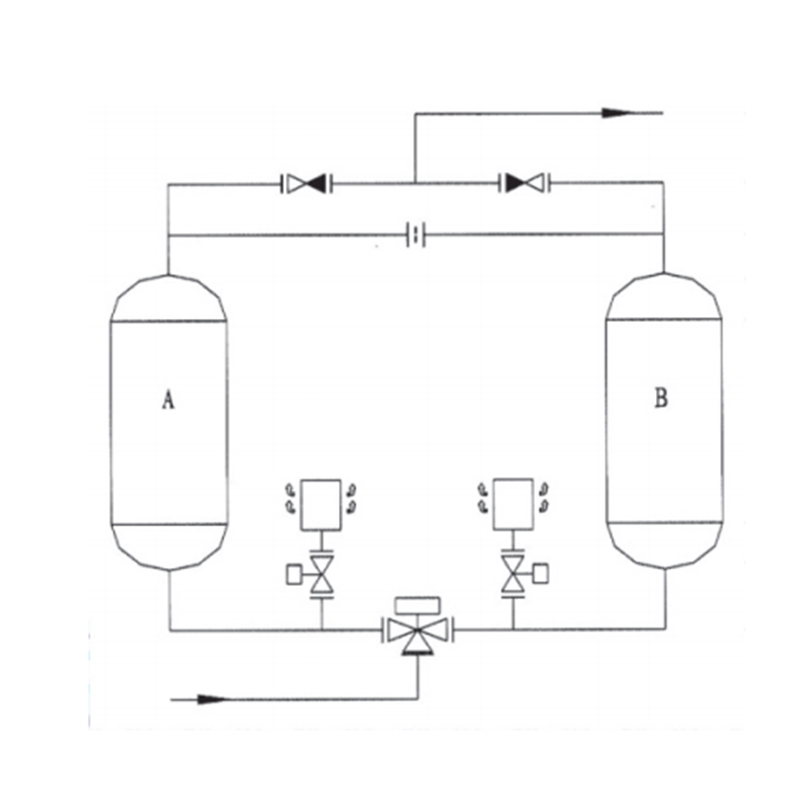

Combining the advantages of pressure swing adsorption and temperature swing adsorption, when adsorbing water vapor at normal temperature and high steam partial pressure (working pressure), it is decomposed at higher temperature and low steam partial pressure, that is, the moisture adsorbed by the adsorbent during the adsorption process, In the regeneration process, it can be completely removed by the combined action of the thermal diffusion of the regeneration gas and the low pressure.

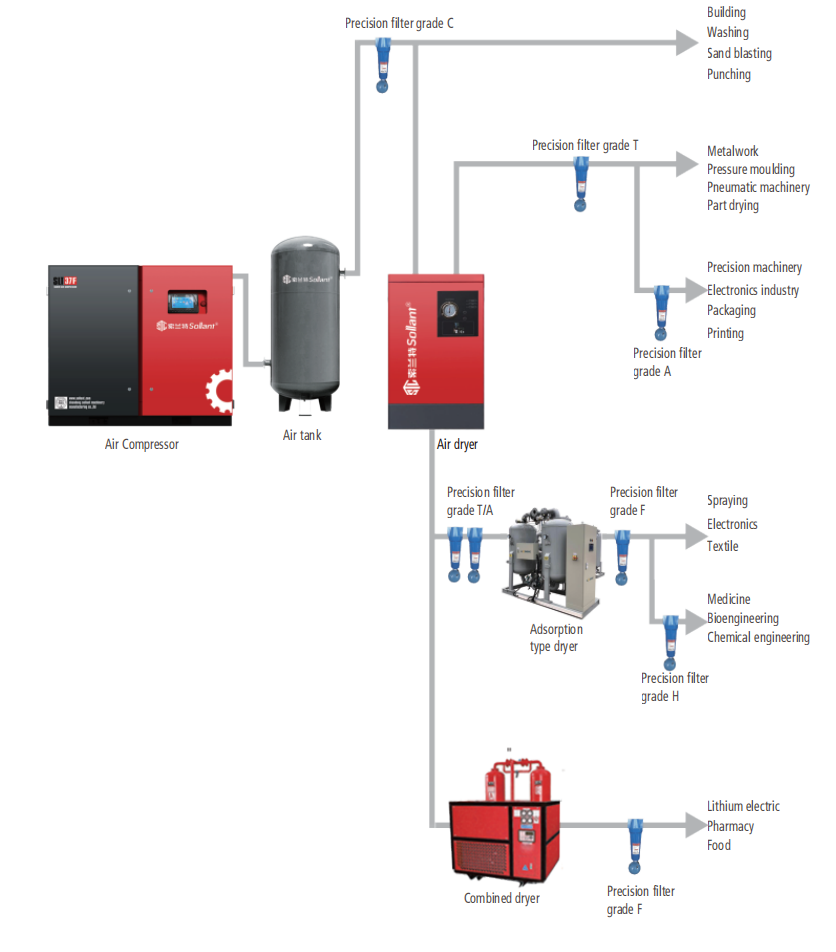

With the advancement of science and technology and the improvement of people’s living standards, in the fields of industry, food and medicine, the requirements for compressed air quality are getting higher and higher. The micro-heat adsorption dryer has low energy consumption, saving production and operation for enterprises Cost; the micro-heat adsorption dryer is compact in structure, simple in operation, safe and reliable, reduces the layout of pipelines and valves in the air compressor station, makes the air purification system simple and smooth, and reduces the investment and construction of external energy facilities and pipeline networks.