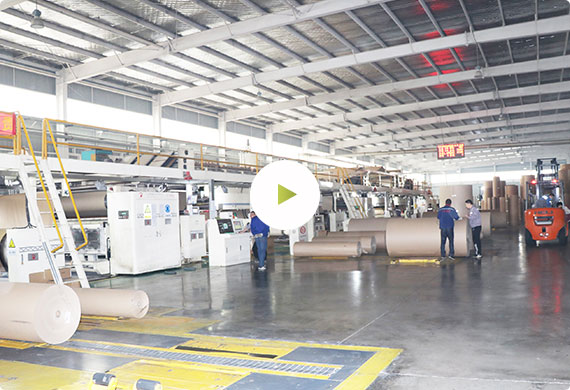

Shandong Zollant machinery manufacturing Co., Ltd is an integrated industry and trade company. The company covers an area of more than ten thousand square meters. With an annual output value of 10 million yuan and fixed assets more than 50 million yuan. We provide customization service of all our Air Compressors.

Zollant Air Compressor Co., Ltd is ruling Towable Air Compressors market over two decades. We always strive to serve in best possible way. Fulfilling our commitment is our motive.