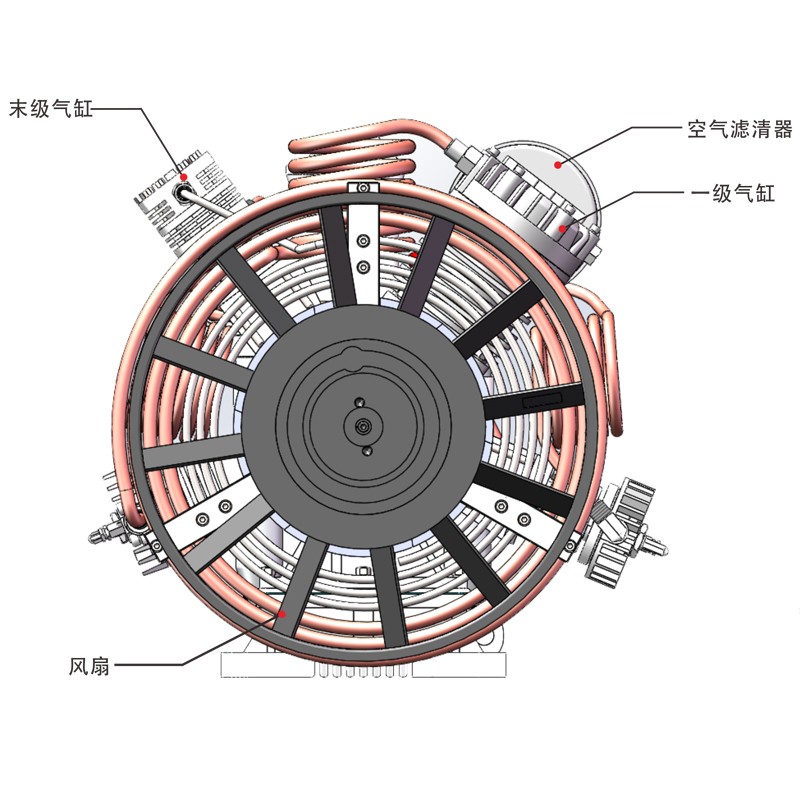

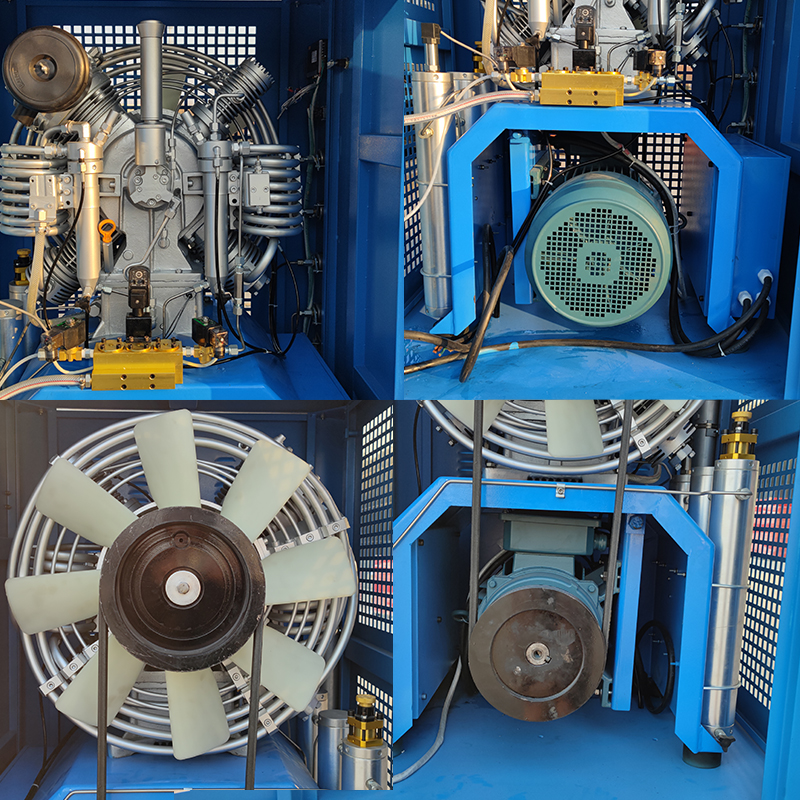

The harmless gas around the compressor is filtered by the intake filter and enters the first-stage cylinder through the intake valve, where the second-stage compression is completed. Part of the heat generated by the compression is dissipated by the cylinder head, related valves, pistons, crankcases and lubricating oil through the air generated by the fan, and the heat retained in the compressed air is dissipated through a long pipeline that acts as a radiator from one stage to the other. go out. The air temperature at the outlet end of the pipe is only 15-20 degrees higher than the ambient temperature.

| High pressure breathing air compressor | |

| Compressed media | Air |

| ambient temperature | -20~+50℃ |

| Safety valve set pressure | 380bar |

| work pressure | 350bar |

| flow | 265 l/min |

| Compression stage | 3 |

| Number of cylinders | 3 |

| host speed | 1650r/min |

| drive mode | Electric motor |

| Control System | Automatic shutdown, automatic pressure regulation, oil shortage shutdown, negative pressure fuel saving device |

| Dimensions (L X W X H) mm | 1100mmX580mmX670mm |

| Weight | 159Kg |

| Air Quality Standards Breathing Air Standards Air | EU EN12021 |

| certified | Export EU CE Certification CCS Classification Society Certification Quality System Certification |

| model | three-phase motor |

| power | 5.5kW |

| Rotating speed | 1440r/min |

| Voltage frequency | 400V/60Hz |

| noise | ≤82dB db |

Sollant is a professional company specializing in the sales, operation and maintenance of compressed air systems and energy-saving services. It is committed to providing users with stable, high-quality and low-cost compressed air. Provide product and service support for machinery, metallurgy, power generation, textile, chemical industry and other industries! After years of development, the company has a group of professional and technical personnel of air compression fluid equipment and rich experience in on-site engineering management, which can provide users with a full range of technical service support.